Gable Shed Building Plans

A-Frame 20 x 10 Outbuilding Crafting Blueprints - Items To Consider While Building A DIY Shed

Position joist so it stands on edge. It is unlikely that you are going to drywall inside or other things that would warrant the best lumber. You could easily adjust the size of your firewood storage shed, if you want to store more wood, as this construction is modular. Anything that prevents a outbuilding from cartwheeling across neighborhood keeps others safe. That number is usually 16'' on center or 24'' on center. (https://sheddrafts.com/8x10-gable-garden-shed-plans-blueprints) Floor joist specifications are provided by an architect or the local building department. Cut a patch with a crosshatch cutout for the vent or obstruction and place it over the top so that it overlaps on top of surrounding paper, and fasten with staples.

Typically sheds are built so that exact dimensions of your floor will be exactly equal to your outbuilding size. Also note if your building is at right angles. It could take hours to hammer in all the nails needed to take care of all foundation, wall, and shed roof framing, not to mention number of blisters you are likely to end up with if you try. Use 8d nails over wall framing and 6d nails when nailing into timber alone. It ensures your outbuilding is well supported, level, and not in direct contact with ground, prolonging life of your shed.

You will need 10 6-foot-long king studs, spaced 16 inches on center. Including shelving, workbenches, cabinets, toolboxes, and hangers. Notch a birdsmouth where it sits on the low wall (read) and extend it past the wall for eaves. The eaves were easy to cut and assemble. Drill pocket holes at both ends of the components, if you want to lock them together tightly. We trim slightly smaller than frame and caulked them in place. As you can see, all my blueprints are so simple that you can adjust their size without much effort. It is critical that all materials are accounted for and in good condition before starting your project.

Cut out a notch in each rafter, using the diagram, in order to fit them into place easily. When you chop a bird mouth, V notch that allows the rafter to rest on the wall, try to segment it close with a circular saw and then finish with a hand saw. You can cross as many braces as necessary to do work you need to do. You'll have to excavate and construct retaining walls or bring in fill. In this case a picture speaks a thousand words. Install sill plates with a bearing area of at least 48 square inches when sill plate bears on concrete or masonry.

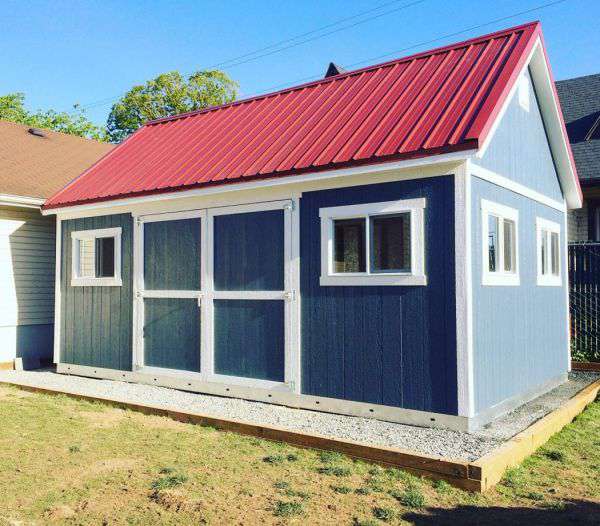

This step is not necessary if you are not worried about locking the shed secure. If you are going for permanently shut then it’s simple, just attach a small square beading of lumber to inside of the window frame. It goes over felt on the gables to prevent windblown moisture getting under felt. And since you don't have to fuss with hinges, installation is much simpler. The last picture shows storage building without the porch roof and unfinished siding. Setting an accurate string line is first done to mark your hole locations. Here are some of ways you'll save with our timber outbuilding diagrams.

There are different ways you could finish base of outbuilding and skirting if used. This step by step DIY woodworking project is about DIY shed door schematics. We stopped building with the walls, as the floors and ceilings vary more. We used a chop saw for this. This is a team operation with the person on the inside drilling holes and the person on the outside inserting machine screws. Whether stepping on a nail, twisting when carrying a load, trimming a finger with a skill saw, broken bones falling off a ladder, or roof surfing on wet sheathing and not surviving impact.

Such an out-of-the-way site might look nice, but it's not very convenient when you must traipse back and forth across the yard every time you need to retrieve a tool. What goes under your outbuilding is up to you. This is a simple constructions but sturdy, so it could pass the test of time. Make sure you leave no gaps and secure sheets tightly to horizontal supports. In this case, the eaves consist only of the rafter tails, and spaces between their ends are left open. Nail 1x2s around door openings at the front of framing. This method ensures that second hole is perfectly aligned.

Piers are supports that are dug into ground and set to a common, level height.