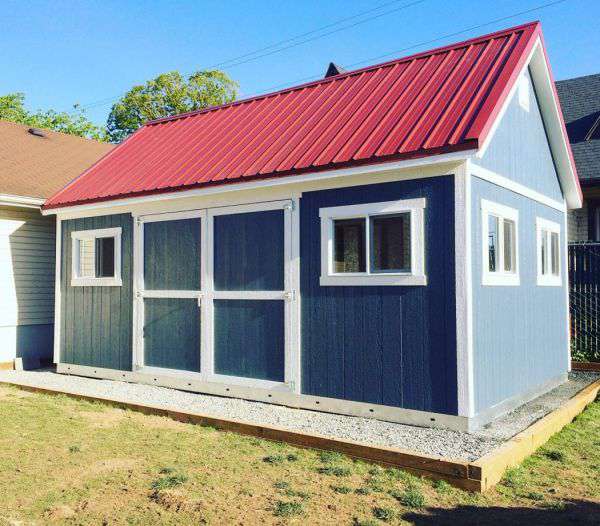

Gable Shed Building Plans

Diagrams To Construct 16 x 24 DIY Shed - How To Guarantee You Do It Right

This ties into my first tip, in that your number one priority should really be accessibility. This also depends on fire resistance of exterior walls, though. This step is not necessary if you are not worried about locking shed secure. You need to decide what it's going to sit on long before you start building. Install perforated hardboard to partition wall in the tool-storage area. We wrapped roof in drip-edge and installed the same shingles (https://sheddrafts.com/gambrel-barn-shed-plans-blueprints) that were in the existing garage. Leave a gap about the width of a nail shank between each board. We had been making shelves and small furniture pieces out of pallets for a couple months and started discussing using pallets as our building material.

For example, if current trusses are made of 2-by-10-inch material, buy 2-by-10 lumber rather than downsizing to 2-by-8 or less. We suggest a cushion storage bag, which is designed for this very thing, but you can also repurpose any large, sealable plastic bags. You may find other uses for short pieces later on. Of course, when building you homemade truss, safety is your first and foremost concern so you have to create sure that the truss is carefully planned, made and installed based on structure's 'standards. Anchor the completed outbuilding to the outside of a building with screws through top back cross piece into building.

Attach them to floor braces rather than the skids for an extra measure of security. Attaching wood framing to a brick wall is an engineering challenge. It was a (our site) typing mistake in cutting list. Finally, install the next lower side girt. Nail floor joists in place, then attach the outer rim trestles to front and back of floor frame. A proper shed foundation is important for two main reasons. During this project you may find it easier to disassemble outbuilding and reassemble it. The ladder backs up to storage racks so its underside is dead space more appropriate for storing items that won't be needed much.

Make sure your frame is square before attaching the back. If you're building on a slab, use pressure-treated lumber for the bottom plates. Cut the side door trim pieces to the correct length and fasten in place down over the siding with 8d non-corrosive nails. All four roof styles, plus nearly all style combinations, can be formed by stick-framing, which means to measure, slice and install each rafter individually, or by installing trusses. To the left of this figure end of burlap sheet would be wrapped around end rafter and stitched to the rafter. Especially if you're using it as a workshop.

Cut the beams at the lines, using a circular saw. The 6-foot overhang extends the working area outside. Many people would dig foundation holes below frost line and pour concrete footers reinforced with rebar. Mark and segment all of notches to match the pattern rafter. Finally install the tin on nailers. The last thing you want to have to do is extend or even tearing it down and start all over because you ended up making it too small. Work with attention and invest in high quality materials, as to use shed for many years in a row. If you're planning to build your shed on an elevated base or foundation, it can still be well secured against wind forces.

Temporary center bracing was used as well to keep everything level and plumb. Once the perpendicular boards are at a guaranteed 90 degree angle then you should nail in a couple more nails right in line with each single nail. The thickness and taper of the shim allows for a perfect transition. Lay two alongside each rafter and screw them to the particle board floor. If the new wall will attach to a framed wall, craft sure it will be positioned at a stud. If you choose to do the ladder overhang assemblies these could actually be installed before your roof sheeting is put down.

Now it's time to start building your pub shed. There are restrictions placed on how close you could create a structure to another on your property. Push ledger firmly against the face of the wall. My platform only has an area of a few square feet, but a larger platform, holding more weight may benefit from power. Take into consideration the style of your home and property. If however you simply want to screw it together this will also work fine. The frame is also responsible for resisting sideways forces due to wind, ground level changes, and, most of all, when you go to move shed.