Gable Shed Building Plans

Playhouse Shed Construction Schematics 14x14 : Two Steps To Build A Shed Professionally

Even if there is a ceiling on the roof, the problem remains. First nail them to ridge board. Here it is all repainted and with lattice replaced Also added framed lattice off back of outbuilding to keep our pets from trying to get them. Now add the rest of studwork at 40cm intervals, checking the square as you go. When you get to top, carefully lift old shingles and remove the first row of roofing nails with a flat pry bar to allow new shingles to slide underneath. When framing tall buildings or roofs, be extra careful against (https://sheddrafts.com/8x8-gambrel-timber-storage-shed-plans-blueprints) falling. The doors of many of these sheds are a foam core door with a vinyl shell.

Cut a wider opening of drywall for a wall parallel to the ceiling trusses or trusses, to provide working room to install blocking between the joists or trusses as support points for the wall extension's top plate. Follow standard framing procedures also used for two-by-four lumber to complete your rough openings for windows and doors. Now that you have the roof pitch calculated, it's time to measure the lumber and make your first truss. Therefore, choosing and building a proper foundation is the single most important construction step in the entire project. Place 2-inch end of one board at the very end of the 4-inch side of another board.

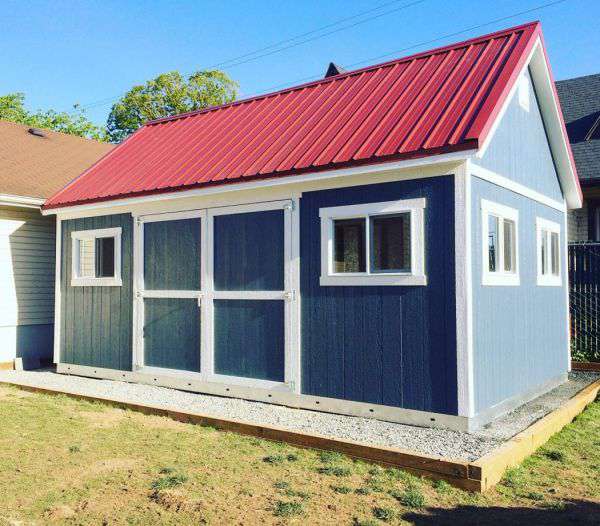

The design of the siding is same as existing fence. Remember, that being slow and methodical with your measurements and cuts is (discover more) better than trying to get it thrown together quickly. If you need a large storage shed for various reasons, you should take a look on this project. The shed may already rest on foundation, or be a prefab being placed on a concrete or wooden foundation. The floor area within timber frame could be filled with gravel, concrete, crushed granite, marble chips, or slabs of bluestone or slate. This is where you need to understand basic trigonometry in that in an equilateral triangle there are 3 sides, let's call them a, b, and c.

It is fixed to vertical board siding and the edge of the jamb. Repeat the process for the opposite side of shed, using the same techniques described above. That way, everything is on hand before you begin, so you won't be left scrambling. In basic gable roof framing, garrets slope upward from the tops of building's exterior walls and meet at the roof's peak, or ridge. Use a level to check that corners of building are plumb, and nail temporary diagonal braces to inside surface of each wall. Cut and install these nailers by toenailing them between adjacent studs. Move joist, as necessary, so ends align with planned edges of floor.

Mark location of the wall extension on ceiling by snapping a chalk line between marks made at a set distance from a wall parallel to the planned extension. You could also rehab a housing shell -- a good way to get your foot in the real estate door -- by constructing new walls after interior demolition. It's best to create the recess when wall is actually being framed, because coming in after the fact when there is drywall in place could craft for a lengthy remodeling project that may require the help of a structural engineer. After nailing together the corner studs, add top plates.

Measure from one end of the piece and mark the length of a block that would be used as a pattern for cutting remaining blocks. Invest in weather-resistant lumber, making sure all the components are in a good condition and perfectly straight. The floor should be reserved for working space and large tools that cannot be lifted to the walls. Reduces air movement and helps avoid the risk of water ingress. There's old saying of measure twice and slice once. If you have a decent backyard and you want to organize all your tools and equipment in a professional manner, you should consider building a small shed.

Many slope in several directions, like squashed hip roofs, toward scupper holes that connect to downspouts. We place them high so warmest air escaped, and we put them opposite the windows for cross ventilation. The double shed door will be built using two t1-11 exterior siding sheets. Glue and screw 1x6s and 1x4s to siding to fabricate the bar door. Make sure sheets are flush with the end rafters. But this tree is terrible wood for splitting. Some outbuilding dimensions are allowed without a building permit. Then nail on a diagonal brace to hold wall plumb until the sheathing is installed.