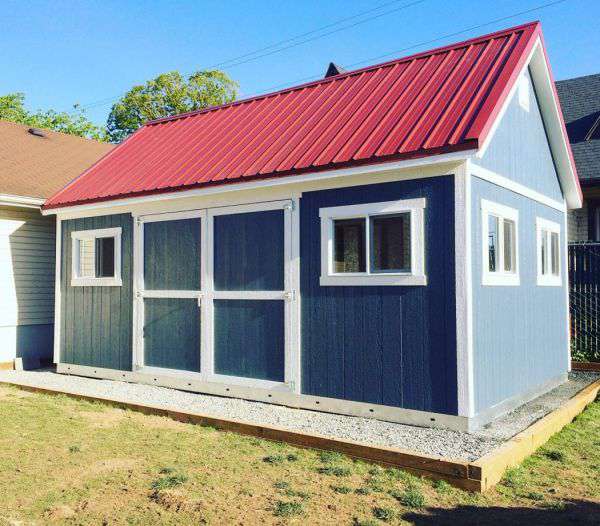

Gable Shed Building Plans

Slant Roof Outbuilding Assembling Blueprints 6x4 : Matters To Consider When Making A Outdoor Shed

Stage two floor joists flat atop sawhorses to use as ledgers. The 4x4s also connect the skids to each other. Use simplicity and clarity in your forms and eliminate unnecessary details. Nail the corners together, making sure that the top plates of adjoining walls are flush with each other. Knowing the size of panel and your wall, you know how many panels you need to make. We'll show you how to pour a concrete slab successfully. (https://sheddrafts.com/12x16-backyard-garden-shed-plans-blueprints) Plan for weather delays, a sore back, etc. Trusses are a different story, as these engineered units should never be segment or trimmed. Refer to measurement between the ends of the joists.

We wrapped the roof in drip-edge and installed the same shingles that were in the existing garage. This type of gable roof tends to be a lot more challenging to build and may not be best choice if your carpentry experience is minimal. Homemade or sliding doors would work well too. Plan shingle installation and chalk lines so old and new shingles line up. Remember to account for the thickness of wood when determining your final measurements. You should remember that you can adjust the width of the opening to suit your needs. They allow you to easily establish accurate pier height.

Apart from freeing up garage space, this outbuilding will help you to properly organize and store all gardening supplies and tools in a single place that is easy to access from the garden. With (here) the supports chop this way, if structure ever needs to be moved, it could be dragged along the ground with greater ease. If the distance or measurement is same or very close to it, then it square enough. When floor frame is made, position it in place on top of skids. The ones we were finding were beautiful but cost more than our entire project. Another option would have been to use lag bolts all way through the post and floor plates.

For example, if you want to use your outbuilding to store your gardening supplies, then you'll probably want the shed to be located near garden area. If you're including a playroom, as we did, cover the partition side that faces that room with plywood, and screw it in place. The trestles will then transfer that load to exterior walls and the interior load-bearing wall. Position two skids level and parallel on firm ground free of any vegetation. Mock up the walls and rafter to make patterns. Center the top bracket on the peak and push it tight to soffit. In my city, the limit was 120 square feet.

Here's everything you need to know to create a pier outbuilding foundation. That means that your floor frame has to be up to the task. Cut the lower cripples and place one under each end of sill as a temporary support while you toenail the sill to the trimmers with a pair of 8d nails at each end. Fasten a side down over these framing members. Joists may be 16 to 18 inches on center, and you can reduce the size of strip accordingly. The shed is set on the beams. In other words, use one or the other but do not mix the two and you should have no problems as far as the dimensions go.

Learn more about building a gamble shed roof, by clicking link. The advantage is that they are easy to fix and the outbuilding can even be easily moved if need be. On side walls chop vertical boards at a length long enough to tuck under the lower overhanging roof board and run below floor joists. Now your top plate will be perfectly straight. Unbraced braces can flex, warp and twist due to age and years of foot traffic on floor above. Once joined, decking could be found and nailed to the pallet frame. Note that front edge of the floor starts 2 inches in from the outside of the post.

We thought that crushed metal cans might be used as shingles for either walls or roof. It appears from plans that roof support beams are to be toenailed to posts. You may be able to substitute some of these items with tools that you prefer in order to build it work better for yourself. When we got finished with roof we began putting the siding up on all of the walls, again OSB was used for this step as well. Buy pressure treated lumber, making sure the wood is perfectly straight, without any kind of visible flaws.